Our partner TIUS together with PLC Systems successfully implemented a project for wireless automated monitoring of temperature and concentration exhaust gas on rotary kilns VP 1-6, which are located on the territory of lime and dolomite shop of metallurgical plant, Severstal group of companies.

The project was implemented using LoRaWan wireless data transfer technology and equipment manufactured by VEGA-Absolut and gas analytical equipment by Analytpribor.

The main objectives of the project were:

- Reduce natural gas consumption by adjusting the thermal regime of rotary kilns;

- Upgrade temperature monitoring equipment of the shop: in front of the filter, loading and hot heads of rotary kilns;

- Increase the efficiency of components analysis of CO and O2 off-gases;

- Reduce labor costs.

To solve these tasks, the obsolete temperature registers were replaced, gas analytical equipment cabinets were installed, sampling lines were laid, sampling probes were tapped into rotary furnaces, monitoring of furnace operation parameters was organized, and data transfer and parsing were implemented.

Gas consumption at rotary kilns is reduced by 1.5 times;

- CO (carbon monoxide) emission into the atmosphere was reduced, and the risk of poisoning of service personnel located in the zone of rotary kiln loading heads by this gas was minimized;

- Monitoring of the main parameters of rotary kilns operation allowed to control the correctness and timeliness of operators' actions;

- The system makes it possible to prevent the furnace mode from reaching the limit states, thus saving their technical resource and funds for their subsequent repair and maintenance.

Full description of the solution and realization of our partners at the link.

Vega BS-1

Vega BS-1 Vega BS-2

Vega BS-2 Vega BS-1.2

Vega BS-1.2 Vega BS-2.2

Vega BS-2.2 Vega BS-0.1

Vega BS-0.1 Vega BS-3

Vega BS-3 Antenna 868-01

Antenna 868-01 Antenna 868-01-A10

Antenna 868-01-A10 Vega SI-11

Vega SI-11 Vega SI-12

Vega SI-12 Vega SI-13-232

Vega SI-13-232 Vega SI-13-485

Vega SI-13-485 Vega SI-21

Vega SI-21 Vega SI-23-232

Vega SI-23-232 Vega SI-23-485

Vega SI-23-485 Vega SI-22

Vega SI-22 Vega NB-11

Vega NB-11 Vega NB-12

Vega NB-12 Vega NB-13

Vega NB-13 Vega NB-14

Vega NB-14 Vega NB-15

Vega NB-15 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE Vega TL-11

Vega TL-11 Vega M-BUS-1

Vega M-BUS-1 Vega M-BUS-2

Vega M-BUS-2 Vega TP-11

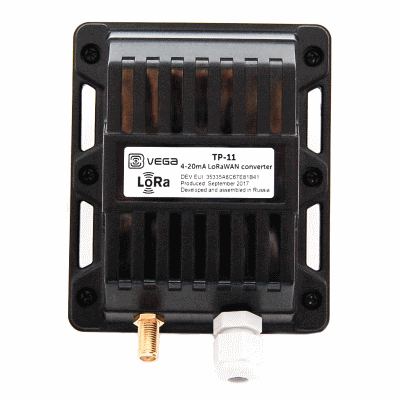

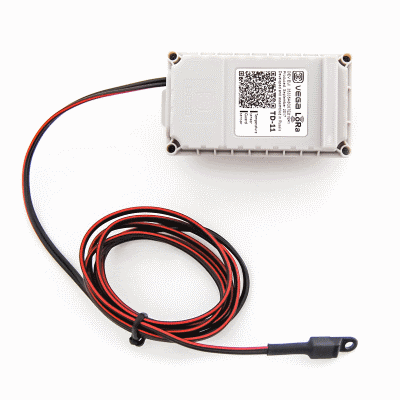

Vega TP-11 Vega TD-11

Vega TD-11 Vega GM-2

Vega GM-2 Vega SH-2

Vega SH-2 Vega LM-1

Vega LM-1 Vega LM-210

Vega LM-210 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE CE2726A R01

CE2726A R01 CE2726A W03

CE2726A W03 CE2727A R02

CE2727A R02 CE2727A B04

CE2727A B04 Mercury 206

Mercury 206 Betar-Vega SGBM-1.6

Betar-Vega SGBM-1.6 Vega TS-11

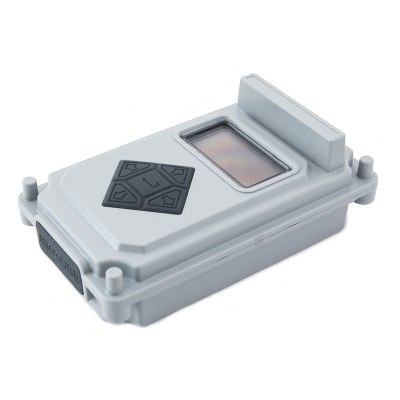

Vega TS-11 Vega Smart-UM0101

Vega Smart-UM0101 Vega Smart-HS0101

Vega Smart-HS0101 Vega Smart-MC0101

Vega Smart-MC0101 Vega Smart-WB0101

Vega Smart-WB0101 Vega Smart Badge

Vega Smart Badge Vega TD-21

Vega TD-21 Vega Smart-AS0101

Vega Smart-AS0101 Vega Smart-MS0101

Vega Smart-MS0101 Vega Smart-SS0101

Vega Smart-SS0101 Vega DP-1

Vega DP-1 Vega USB-UART

Vega USB-UART Vega FSK Dongle

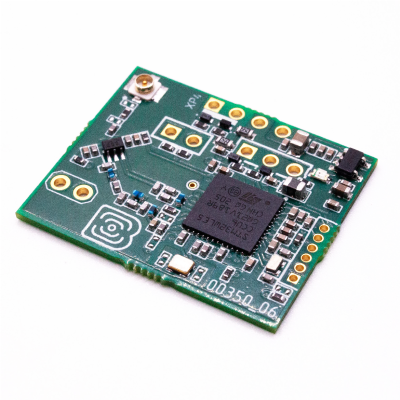

Vega FSK Dongle Vega RF32WL

Vega RF32WL Vega RM868-UFL

Vega RM868-UFL Vega RM868-CPA

Vega RM868-CPA VEKTOR-101

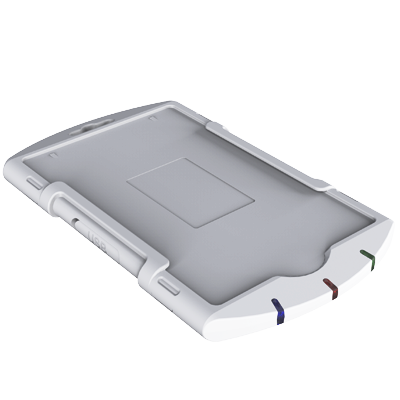

VEKTOR-101 Vega Smart Tab

Vega Smart Tab Vega BP 3.6V

Vega BP 3.6V Vega Smart Tab-S

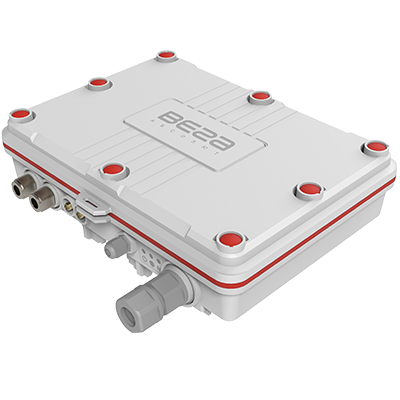

Vega Smart Tab-S Vega BS-4

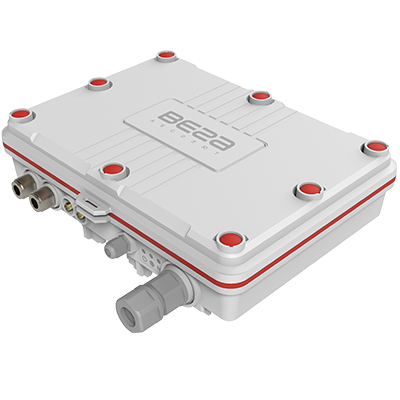

Vega BS-4 Vega BS-4 PRO

Vega BS-4 PRO