Our partner TIUS together with PLC Systems successfully implemented a comprehensive project for the dispatching of thermal units, as well as wireless automated energy metering and monitoring of compressor units at the site of the Biosintez PJSC plant. Part of the project in terms of energy metering and monitoring of compressors was carried out on the basis of our equipment using Industrial Internet of Things (IIoT) technologies and the LoRaParsing parsing module for LoRaWAN® networks developed by PLCSystems OOO.

The main objectives of the project were:

- Providing wireless energy metering of water and electricity in all workshops of the enterprise based on LoRaWAN® technology;

- Organization of a dispatching system for engineering systems, which includes control of the operation of air compressors in workshops, which implies indication of the normal / emergency value of compressed air pressure at the upper level of the system;

- Reducing labor costs for obtaining data on the engineering networks of the plant, optimizing the time bypassing monitoring points by operational personnel;

- Ensuring the forecast of equipment failures and breakdowns, building an alarm system for overpressure on compressors;

- Improving the efficiency of analysis and planning of energy consumption at the enterprise;

- Providing management and operational personnel with remote access to information on the operation of the engineering system at the enterprise and automating reporting.

Project results:

- LoRaWAN® network coverage was organized throughout the Biosintez plant, including in wells;

- Organized wireless data collection of all cold water meters in industrial workshops, as well as introductory chambers in wells outside the enterprise, data transmission once an hour. As a result, there is no need to bypass objects and manually collect data;

- Wireless data collection from PSC-3ART electric meters was organized via the RS-485 interface via the LoRaWAN® network, PLCSystems OOO implemented from scratch its own algorithm for polling instrument data and full support for the meter protocol at the top level;

- Wireless monitoring of compressor pressure in workshops was organized, as well as an alarm system for pressure gauges exceeding the lower / upper limits, the firmware of the VEGA SI-11 modem for this task was improved to optimize the operating mode and generate alarms;

- A dispatching system for steam metering units was organized, data collection via a wired Ethernet network into a single system based on Tibbo Aggregate;

- LoRaWAN® network management, processing of incoming data, their visualization, storage of archives, analytics and forecasts on resource consumption on a single server using the Tibbo Aggregate IoT platform and LoRaParsing software developed by PLCSystems OOO were organized.

To manage the LoRaWAN® network in this project, a single LoRaParsing server is used, which ensures the processing of all data from the monitoring objects and integration with the client's corporate DBMS.

Full description of the solution and actual realization by our partners under the link.

Vega BS-1

Vega BS-1 Vega BS-2

Vega BS-2 Vega BS-1.2

Vega BS-1.2 Vega BS-2.2

Vega BS-2.2 Vega BS-0.1

Vega BS-0.1 Vega BS-3

Vega BS-3 Antenna 868-01

Antenna 868-01 Antenna 868-01-A10

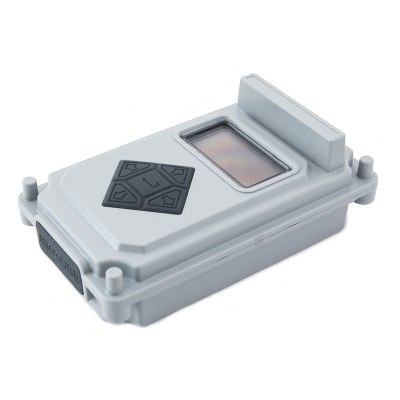

Antenna 868-01-A10 Vega SI-11

Vega SI-11 Vega SI-12

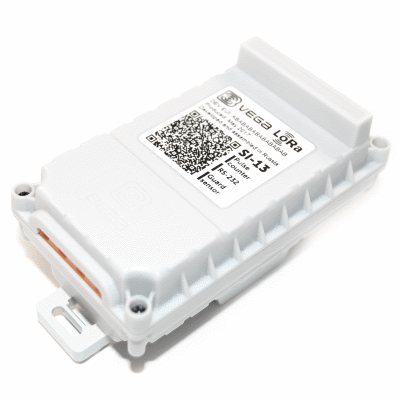

Vega SI-12 Vega SI-13-232

Vega SI-13-232 Vega SI-13-485

Vega SI-13-485 Vega SI-21

Vega SI-21 Vega SI-23-232

Vega SI-23-232 Vega SI-23-485

Vega SI-23-485 Vega SI-22

Vega SI-22 Vega NB-11

Vega NB-11 Vega NB-12

Vega NB-12 Vega NB-13

Vega NB-13 Vega NB-14

Vega NB-14 Vega NB-15

Vega NB-15 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE Vega TL-11

Vega TL-11 Vega M-BUS-1

Vega M-BUS-1 Vega M-BUS-2

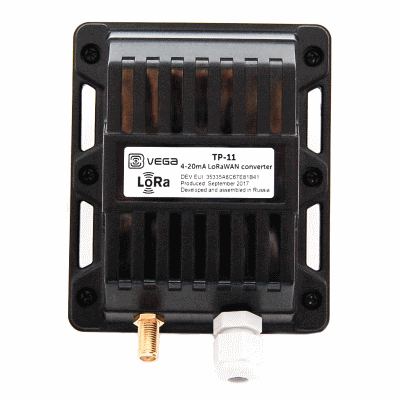

Vega M-BUS-2 Vega TP-11

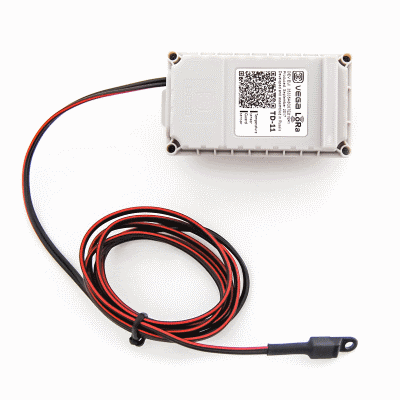

Vega TP-11 Vega TD-11

Vega TD-11 Vega GM-2

Vega GM-2 Vega SH-2

Vega SH-2 Vega LM-1

Vega LM-1 Vega LM-210

Vega LM-210 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE CE2726A R01

CE2726A R01 CE2726A W03

CE2726A W03 CE2727A R02

CE2727A R02 CE2727A B04

CE2727A B04 Mercury 206

Mercury 206 Betar-Vega SGBM-1.6

Betar-Vega SGBM-1.6 Vega TS-11

Vega TS-11 Vega Smart-UM0101

Vega Smart-UM0101 Vega Smart-HS0101

Vega Smart-HS0101 Vega Smart-MC0101

Vega Smart-MC0101 Vega Smart-WB0101

Vega Smart-WB0101 Vega Smart Badge

Vega Smart Badge Vega TD-21

Vega TD-21 Vega Smart-AS0101

Vega Smart-AS0101 Vega Smart-MS0101

Vega Smart-MS0101 Vega Smart-SS0101

Vega Smart-SS0101 Vega DP-1

Vega DP-1 Vega USB-UART

Vega USB-UART Vega FSK Dongle

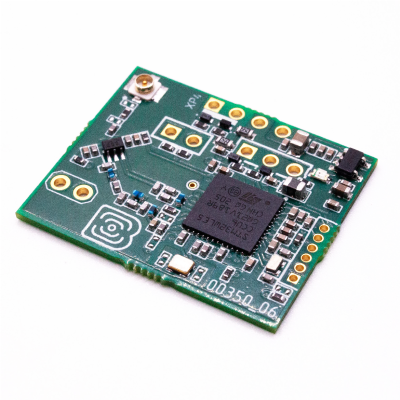

Vega FSK Dongle Vega RF32WL

Vega RF32WL Vega RM868-UFL

Vega RM868-UFL Vega RM868-CPA

Vega RM868-CPA VEKTOR-101

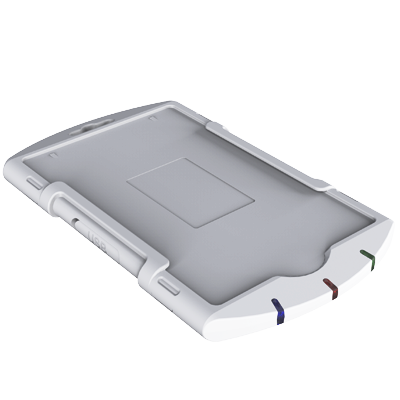

VEKTOR-101 Vega Smart Tab

Vega Smart Tab Vega BP 3.6V

Vega BP 3.6V Vega Smart Tab-S

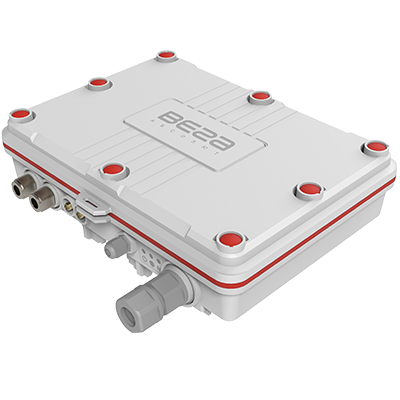

Vega Smart Tab-S Vega BS-4

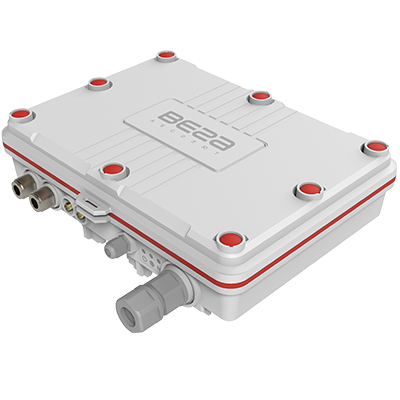

Vega BS-4 Vega BS-4 PRO

Vega BS-4 PRO