Our partner, “TIUS”, successfully implemented a wireless automated vibration monitoring system. The system monitors front and rear bearings of electric motors and fans on the production line.

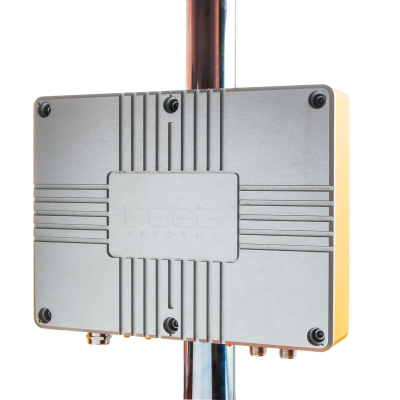

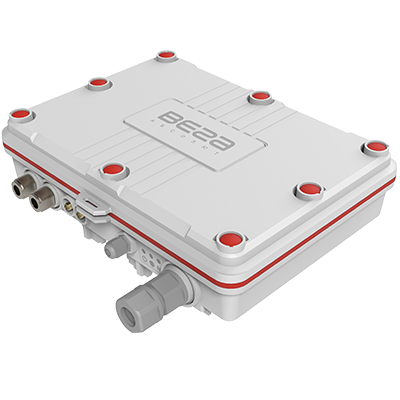

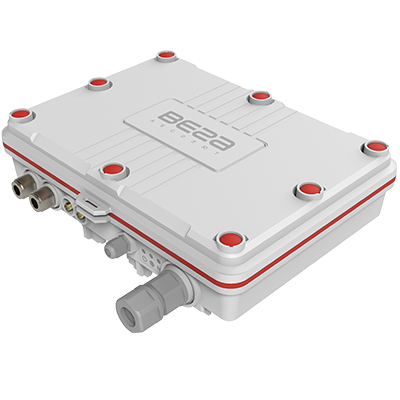

The solution leverages modern Industrial Internet of Things (IIoT) technologies and LoRaWAN wireless communication. The core infrastructure consists of LoRaWAN base stations manufactured in-house by our own production facilities.

The objectives of the project were:

- Enable remote monitoring of vibration parameters in fan and electric motor bearings.

- Facilitate timely intervention to prevent unplanned downtime and production of defective products.

- Detect equipment defects and faults at an early stage, reducing maintenance costs for monitored assets.

- Enhance the efficiency of vibration data analysis and optimization of fan operating regimes.

Prior to project implementation, a comprehensive preliminary survey of the entire facility was conducted. Specialists from TIUS performed a pre-project assessment and LoRaWAN network radio planning, including hard-to-reach areas across the enterprise site. Based on this, a coverage map was developed, detailing signal strength, data transmission rates, and penetration range at various locations, ensuring reliable connectivity throughout the entire premises. Optimal locations for equipment installation (LoRaWAN base stations and sensors) were evaluated and selected, taking into account operational specifics and maintenance requirements. Device interoperability was rigorously tested and fine-tuned to ensure the solution is fully ready for deployment.

Completed work:

1. Installation, initial configuration, and activation of equipment (LoRaWAN base station and vibration sensors) across the entire facility.2. Implementation of real-time monitoring of key equipment parameters, with measurements and controls performed every 15 minutes:

- Vibration monitoring of the front bearings of electric motors

- Vibration monitoring of the front bearings of fans

4. Comprehensive training provided to enterprise personnel for operation of LoRaWAN devices and the server; successful warranty testing and system fine-tuning completed.

5. A customized web interface was implemented at the system’s top level, fully aligned with the enterprise’s corporate color scheme, logos, and design elements.

Results:

2. Early fault detection enabled the client to reduce repair costs and cut equipment downtime by 2–3 time.

3. The monitoring system optimized operational modes, resulting in improved product quality and extended equipment service life.

For a full description of the solution and its implementation by our partners, see here.

Vega BS-1

Vega BS-1 Vega BS-2

Vega BS-2 Vega BS-1.2

Vega BS-1.2 Vega BS-2.2

Vega BS-2.2 Vega BS-0.1

Vega BS-0.1 Vega BS-3

Vega BS-3 Antenna 868-01

Antenna 868-01 Antenna 868-01-A10

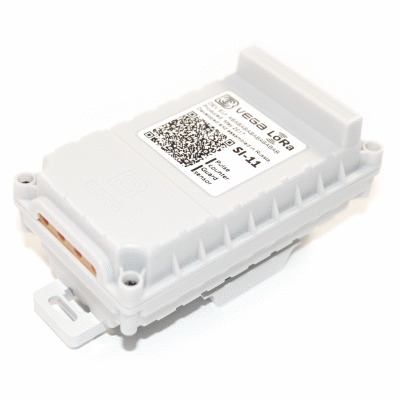

Antenna 868-01-A10 Vega SI-11

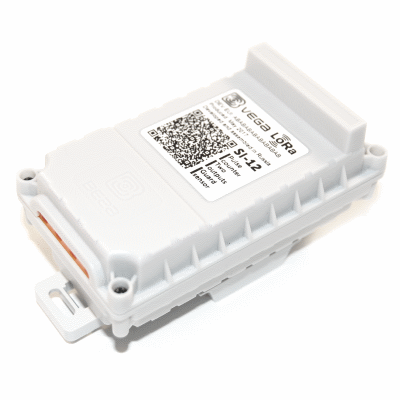

Vega SI-11 Vega SI-12

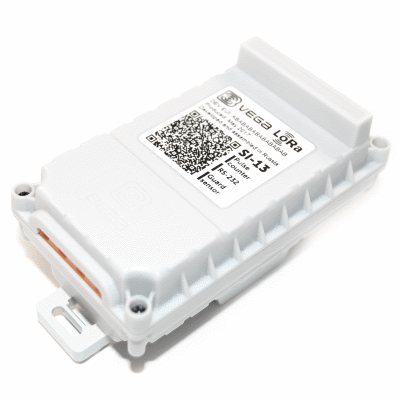

Vega SI-12 Vega SI-13-232

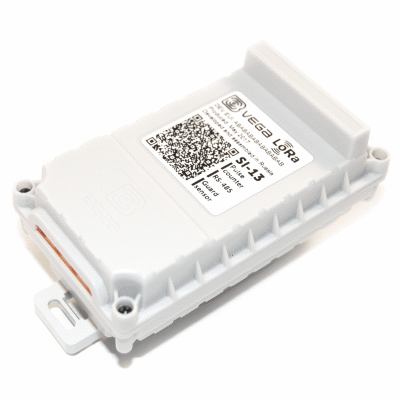

Vega SI-13-232 Vega SI-13-485

Vega SI-13-485 Vega SI-21

Vega SI-21 Vega SI-23-232

Vega SI-23-232 Vega SI-23-485

Vega SI-23-485 Vega SI-22

Vega SI-22 Vega NB-11

Vega NB-11 Vega NB-12

Vega NB-12 Vega NB-13

Vega NB-13 Vega NB-14

Vega NB-14 Vega NB-15

Vega NB-15 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE Vega TL-11

Vega TL-11 Vega M-BUS-1

Vega M-BUS-1 Vega M-BUS-2

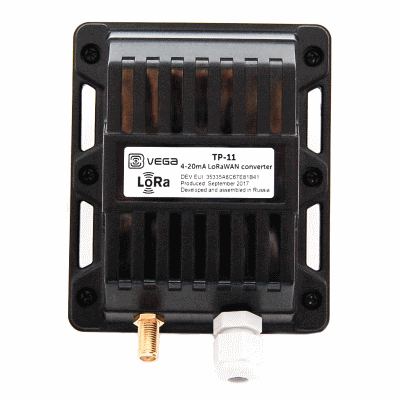

Vega M-BUS-2 Vega TP-11

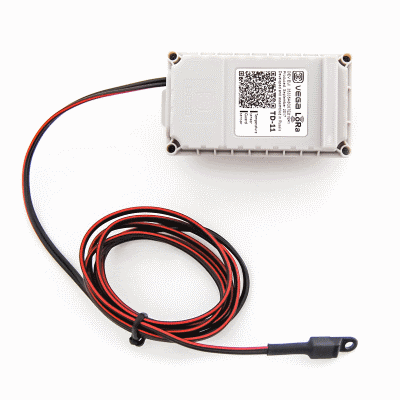

Vega TP-11 Vega TD-11

Vega TD-11 Vega GM-2

Vega GM-2 Vega SH-2

Vega SH-2 Vega LM-1

Vega LM-1 Vega LM-210

Vega LM-210 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE CE2726A R01

CE2726A R01 CE2726A W03

CE2726A W03 CE2727A R02

CE2727A R02 CE2727A B04

CE2727A B04 Mercury 206

Mercury 206 Betar-Vega SGBM-1.6

Betar-Vega SGBM-1.6 Vega TS-11

Vega TS-11 Vega Smart-UM0101

Vega Smart-UM0101 Vega Smart-HS0101

Vega Smart-HS0101 Vega Smart-MC0101

Vega Smart-MC0101 Vega Smart-WB0101

Vega Smart-WB0101 Vega Smart Badge

Vega Smart Badge Vega TD-21

Vega TD-21 Vega Smart-AS0101

Vega Smart-AS0101 Vega Smart-MS0101

Vega Smart-MS0101 Vega Smart-SS0101

Vega Smart-SS0101 Vega DP-1

Vega DP-1 Vega USB-UART

Vega USB-UART Vega FSK Dongle

Vega FSK Dongle Vega RF32WL

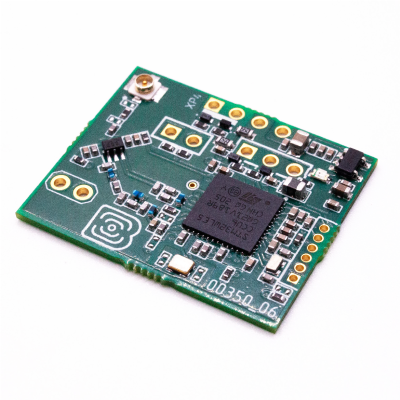

Vega RF32WL Vega RM868-UFL

Vega RM868-UFL Vega RM868-CPA

Vega RM868-CPA VEKTOR-101

VEKTOR-101 Vega Smart Tab

Vega Smart Tab Vega BP 3.6V

Vega BP 3.6V Vega Smart Tab-S

Vega Smart Tab-S Vega BS-4

Vega BS-4 Vega BS-4 PRO

Vega BS-4 PRO