Our partner TIUS together with PLC Systems implemented a project for wireless automated monitoring of vibration and temperature parameters of bearings of electric motors, gearboxes and rollers of the NTA-4 unit, which is located in the metal pickling shop (CTM) of the Cherepovets Metallurgical Plant, a group of companies PJSC Severstal.The project was implemented using Industrial Internet of Things (IIoT) technologies, LoRaWAN® wireless data transmission technology and vibration control tools. Within the framework of the project, LoRaWAN® equipment manufactured by Vega-Absolute was used.Main Tasks:

- Provide remote monitoring of vibration and temperature parameters at the site of the continuous pickling unit (NTA-4);

- Reduce labor costs for obtaining data and reduce the time for bypassing the territory of the NTA-4 workshop by operational personnel;

- Based on the data obtained, to provide a forecast of failures and breakdowns of equipment for drive, tensioning, centering devices, as well as critical units of storage carts;

- To increase the efficiency of analysis and planning of operating modes of the NTA-4 production line;

- Provide operational personnel with access to information about the operation of the dynamic equipment of the main mechanical units of the production line of the NTA-4 shop.

Project results:

- Reduced response time to unforeseen breakdowns and accidents of electric motors, gearboxes and rollers by 4 times;

- This vibration monitoring system provided the client with pre-repair analytics of the unit based on the analysis of the received data;

- An engine malfunction was detected on Uncoiler No. 1 in a timely manner, which prevented a line failure and a long downtime of the workshop;

- Improved resource and time planning for scheduled repairs.

Full description of the solution and implementation of our partners link.

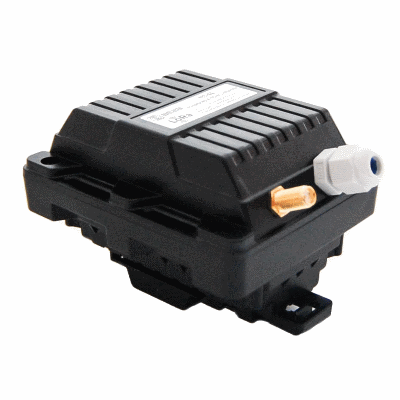

Vega BS-1

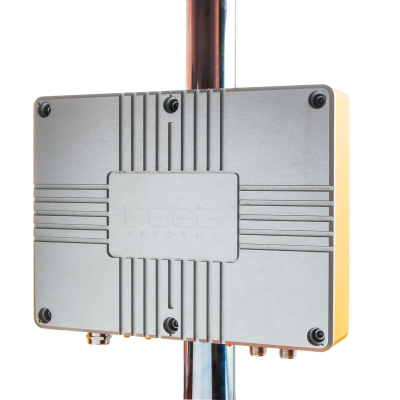

Vega BS-1 Vega BS-2

Vega BS-2 Vega BS-1.2

Vega BS-1.2 Vega BS-2.2

Vega BS-2.2 Vega BS-0.1

Vega BS-0.1 Vega BS-3

Vega BS-3 Antenna 868-01

Antenna 868-01 Antenna 868-01-A10

Antenna 868-01-A10 Vega SI-11

Vega SI-11 Vega SI-12

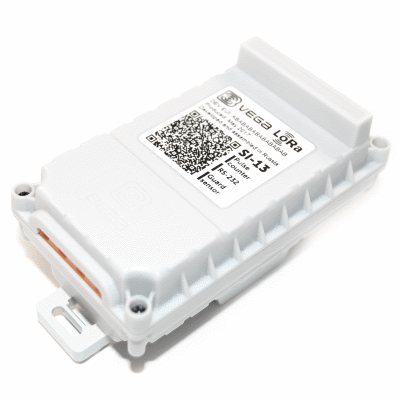

Vega SI-12 Vega SI-13-232

Vega SI-13-232 Vega SI-13-485

Vega SI-13-485 Vega SI-21

Vega SI-21 Vega SI-23-232

Vega SI-23-232 Vega SI-23-485

Vega SI-23-485 Vega SI-22

Vega SI-22 Vega NB-11

Vega NB-11 Vega NB-12

Vega NB-12 Vega NB-13

Vega NB-13 Vega NB-14

Vega NB-14 Vega NB-15

Vega NB-15 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE Vega TL-11

Vega TL-11 Vega M-BUS-1

Vega M-BUS-1 Vega M-BUS-2

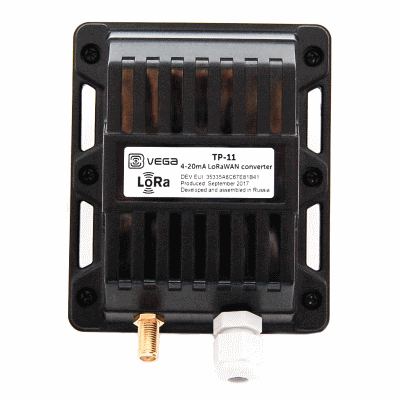

Vega M-BUS-2 Vega TP-11

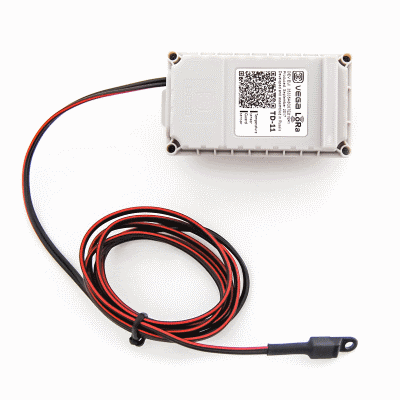

Vega TP-11 Vega TD-11

Vega TD-11 Vega GM-2

Vega GM-2 Vega SH-2

Vega SH-2 Vega LM-1

Vega LM-1 Vega LM-210

Vega LM-210 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE CE2726A R01

CE2726A R01 CE2726A W03

CE2726A W03 CE2727A R02

CE2727A R02 CE2727A B04

CE2727A B04 Mercury 206

Mercury 206 Betar-Vega SGBM-1.6

Betar-Vega SGBM-1.6 Vega TS-11

Vega TS-11 Vega Smart-UM0101

Vega Smart-UM0101 Vega Smart-HS0101

Vega Smart-HS0101 Vega Smart-MC0101

Vega Smart-MC0101 Vega Smart-WB0101

Vega Smart-WB0101 Vega Smart Badge

Vega Smart Badge Vega TD-21

Vega TD-21 Vega Smart-AS0101

Vega Smart-AS0101 Vega Smart-MS0101

Vega Smart-MS0101 Vega Smart-SS0101

Vega Smart-SS0101 Vega DP-1

Vega DP-1 Vega USB-UART

Vega USB-UART Vega FSK Dongle

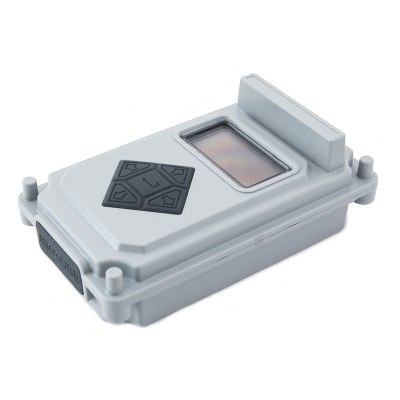

Vega FSK Dongle Vega RF32WL

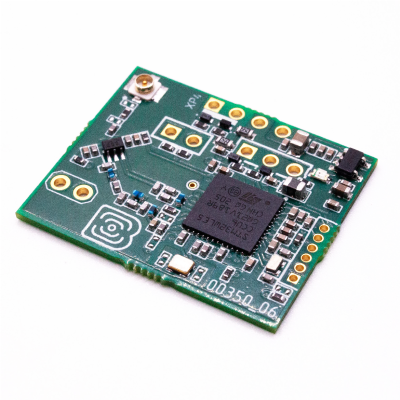

Vega RF32WL Vega RM868-UFL

Vega RM868-UFL Vega RM868-CPA

Vega RM868-CPA VEKTOR-101

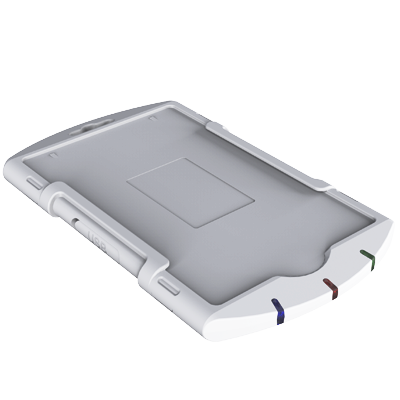

VEKTOR-101 Vega Smart Tab

Vega Smart Tab Vega BP 3.6V

Vega BP 3.6V Vega Smart Tab-S

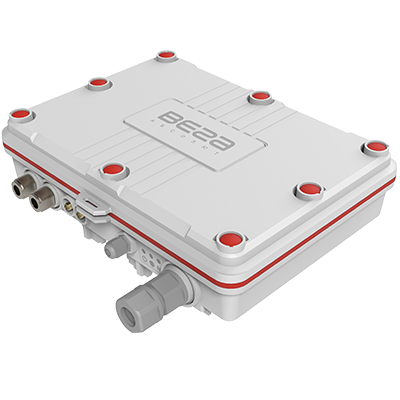

Vega Smart Tab-S Vega BS-4

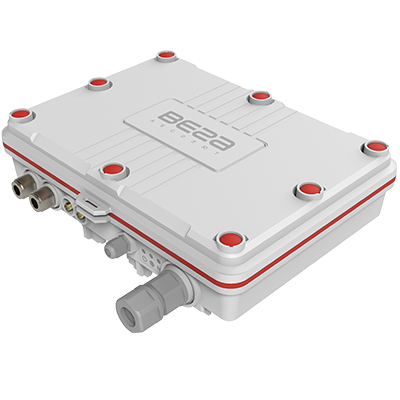

Vega BS-4 Vega BS-4 PRO

Vega BS-4 PRO