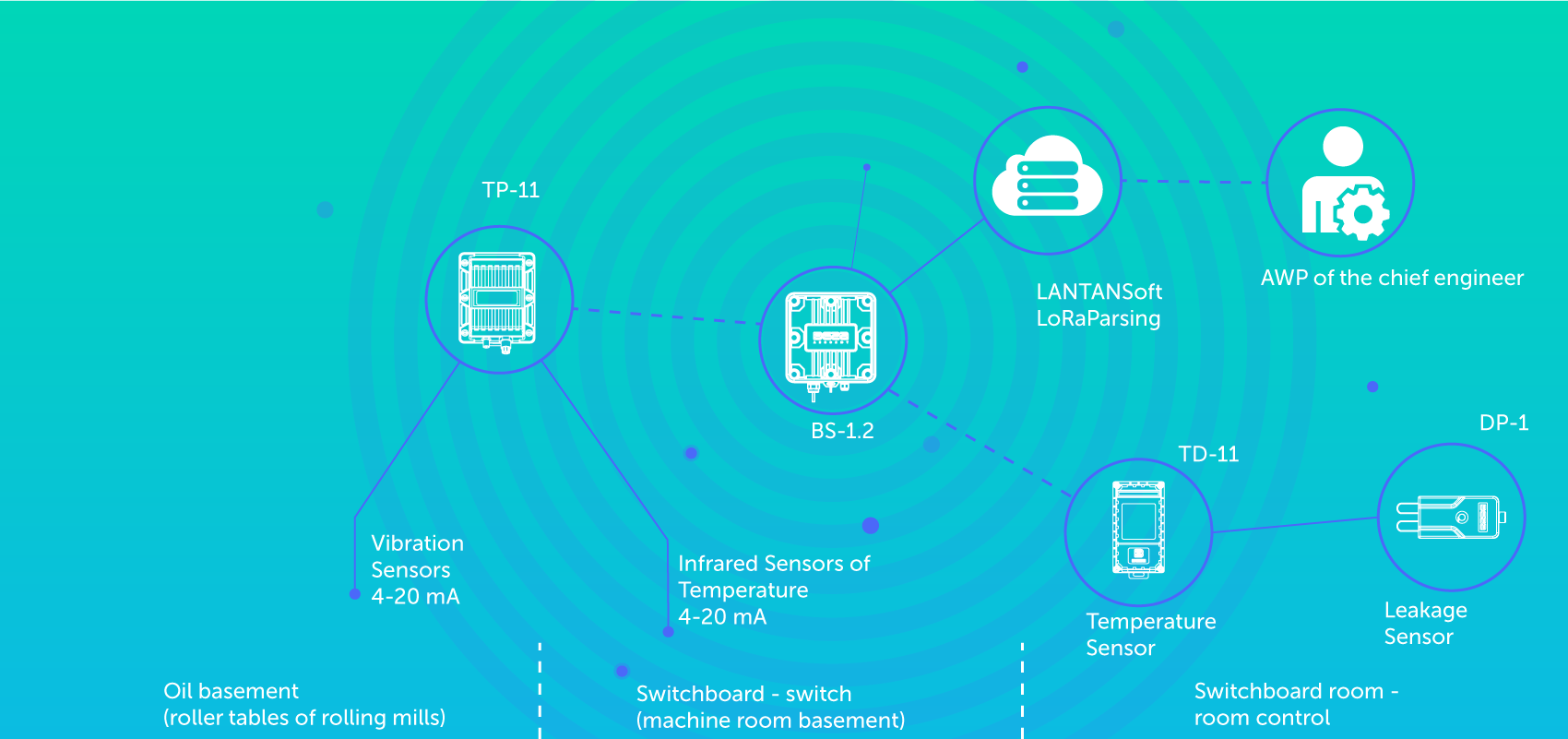

Our partner TIUS together with PLC Systems successfully implemented a project for wireless automated monitoring of vibration and temperature parameters at the section of the rolling tables of the rolling mill of the sheet-rolling workshop of «Severstal». This solution was built on our equipment, using the technologies of the Industrial Internet of Things (IIoT) and the LoRaParsing parsing module for LoRaWAN® networks developed by «PLCSystems».

The main objectives of the project were:

- Provide remote monitoring of vibration and temperature parameters at the section of the rolling table of the rolling mill;

- Provide remote monitoring of temperature and flooding in the electrical room of the powerhouse basement, temperature on the control equipment of the main drive of the rolling stand;

- Reduce labor costs for obtaining data and reduce the time required to walk around the territory of a sheet-rolling shop by operational personnel;

- Provide a forecast of failures and breakdowns of rolling mill equipment and control equipment of the main drive based on the data obtained;

- Increase the efficiency of analysis and planning of rolling mill operating modes;

- Provide operational personnel with access to information and automate the generation of reports on the operation of dynamic rolling mill equipment.

Result of IoT using is an increase of efficiency of processes monitoring and managing and in the end the profitability increasing.

Equipping production with temperature and vibration sensors allows you to receive information in real time and achieve the following results:

- Reduce the response time to unforeseen breakdowns and accidents of rolling mill roller tables and control equipment of the main drive by 3 times;

- Provide pre-maintenance analytics based on the analysis of the received data;

- Eliminate the need to bypass flooding facilities in the rolling mill.

To manage the LoRaWAN® network in this project, a single LoRaParsing server is used, which ensures the processing of all data from the monitoring objects and integration with the client's corporate DBMS.

Full description of the solution and actual realization by our partners under the link.

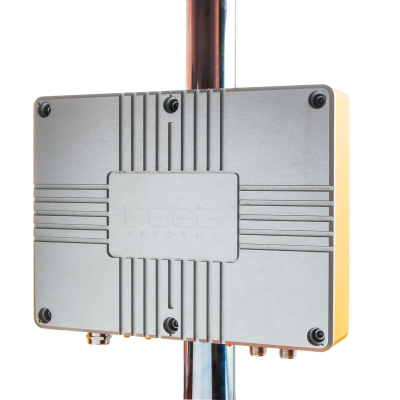

Vega BS-1

Vega BS-1 Vega BS-2

Vega BS-2 Vega BS-1.2

Vega BS-1.2 Vega BS-2.2

Vega BS-2.2 Vega BS-0.1

Vega BS-0.1 Vega BS-3

Vega BS-3 Antenna 868-01

Antenna 868-01 Antenna 868-01-A10

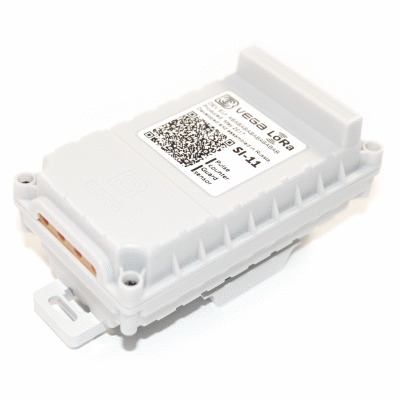

Antenna 868-01-A10 Vega SI-11

Vega SI-11 Vega SI-12

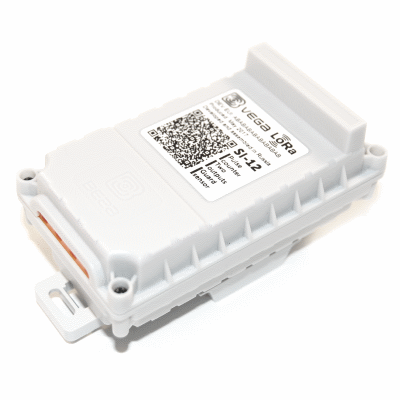

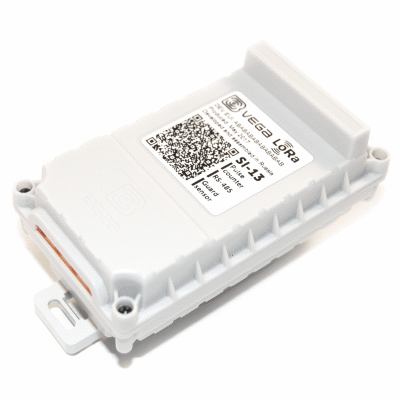

Vega SI-12 Vega SI-13-232

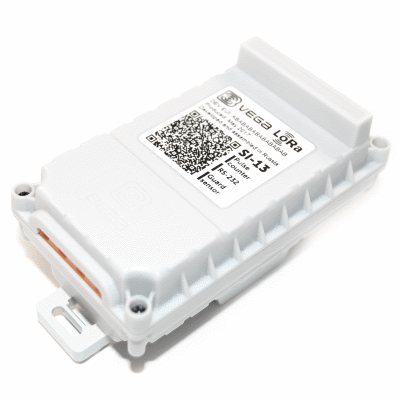

Vega SI-13-232 Vega SI-13-485

Vega SI-13-485 Vega SI-21

Vega SI-21 Vega SI-23-232

Vega SI-23-232 Vega SI-23-485

Vega SI-23-485 Vega SI-22

Vega SI-22 Vega NB-11

Vega NB-11 Vega NB-12

Vega NB-12 Vega NB-13

Vega NB-13 Vega NB-14

Vega NB-14 Vega NB-15

Vega NB-15 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE Vega TL-11

Vega TL-11 Vega M-BUS-1

Vega M-BUS-1 Vega M-BUS-2

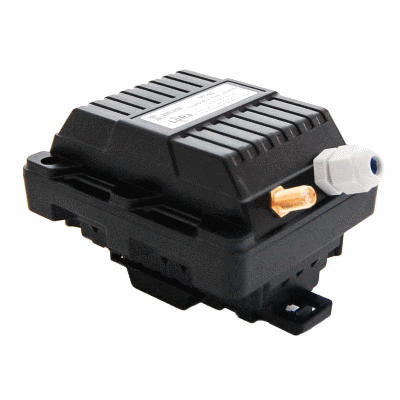

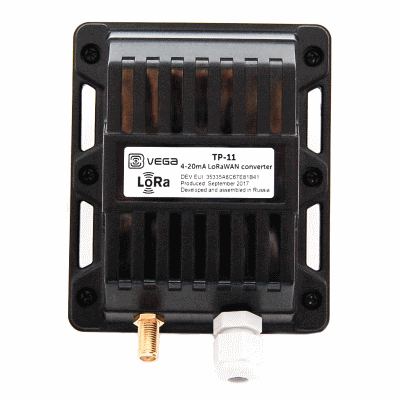

Vega M-BUS-2 Vega TP-11

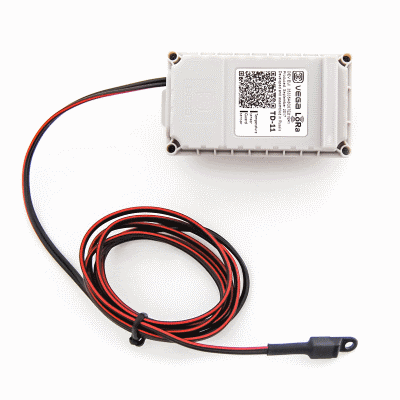

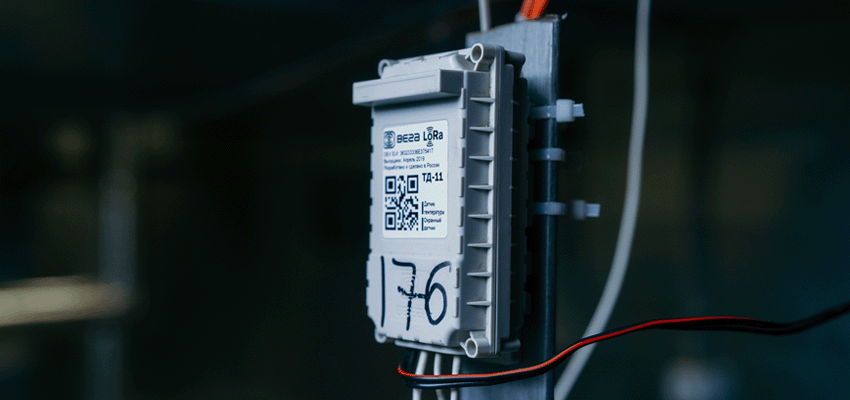

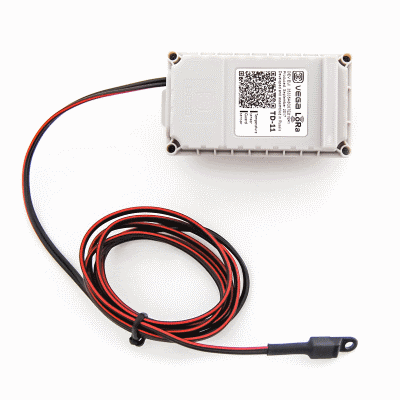

Vega TP-11 Vega TD-11

Vega TD-11 Vega GM-2

Vega GM-2 Vega SH-2

Vega SH-2 Vega LM-1

Vega LM-1 Vega LM-210

Vega LM-210 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE CE2726A R01

CE2726A R01 CE2726A W03

CE2726A W03 CE2727A R02

CE2727A R02 CE2727A B04

CE2727A B04 Mercury 206

Mercury 206 Betar-Vega SGBM-1.6

Betar-Vega SGBM-1.6 Vega TS-11

Vega TS-11 Vega Smart-UM0101

Vega Smart-UM0101 Vega Smart-HS0101

Vega Smart-HS0101 Vega Smart-MC0101

Vega Smart-MC0101 Vega Smart-WB0101

Vega Smart-WB0101 Vega Smart Badge

Vega Smart Badge Vega TD-21

Vega TD-21 Vega Smart-AS0101

Vega Smart-AS0101 Vega Smart-MS0101

Vega Smart-MS0101 Vega Smart-SS0101

Vega Smart-SS0101 Vega DP-1

Vega DP-1 Vega USB-UART

Vega USB-UART Vega FSK Dongle

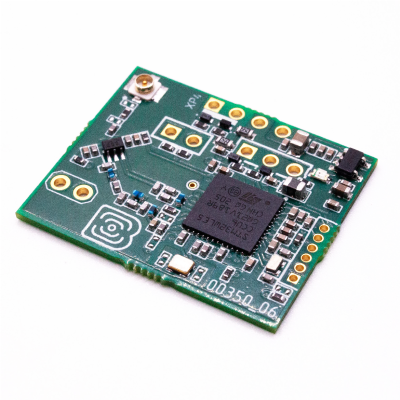

Vega FSK Dongle Vega RF32WL

Vega RF32WL Vega RM868-UFL

Vega RM868-UFL Vega RM868-CPA

Vega RM868-CPA VEKTOR-101

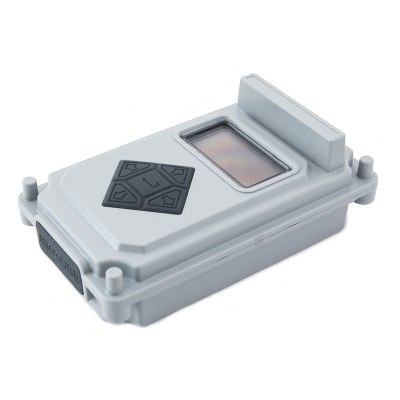

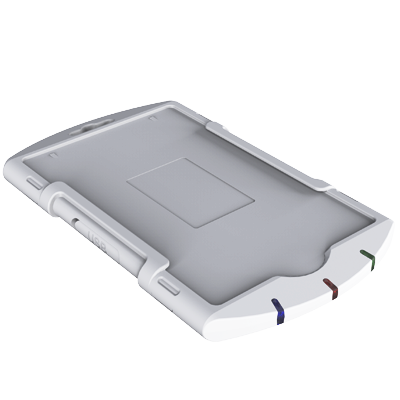

VEKTOR-101 Vega Smart Tab

Vega Smart Tab Vega BP 3.6V

Vega BP 3.6V Vega Smart Tab-S

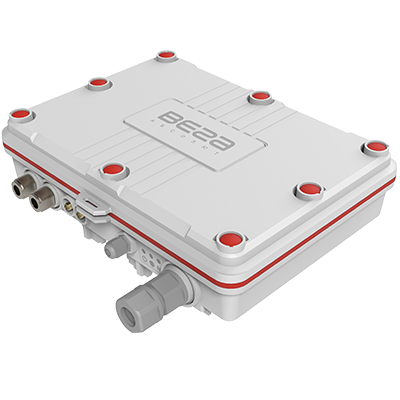

Vega Smart Tab-S Vega BS-4

Vega BS-4 Vega BS-4 PRO

Vega BS-4 PRO