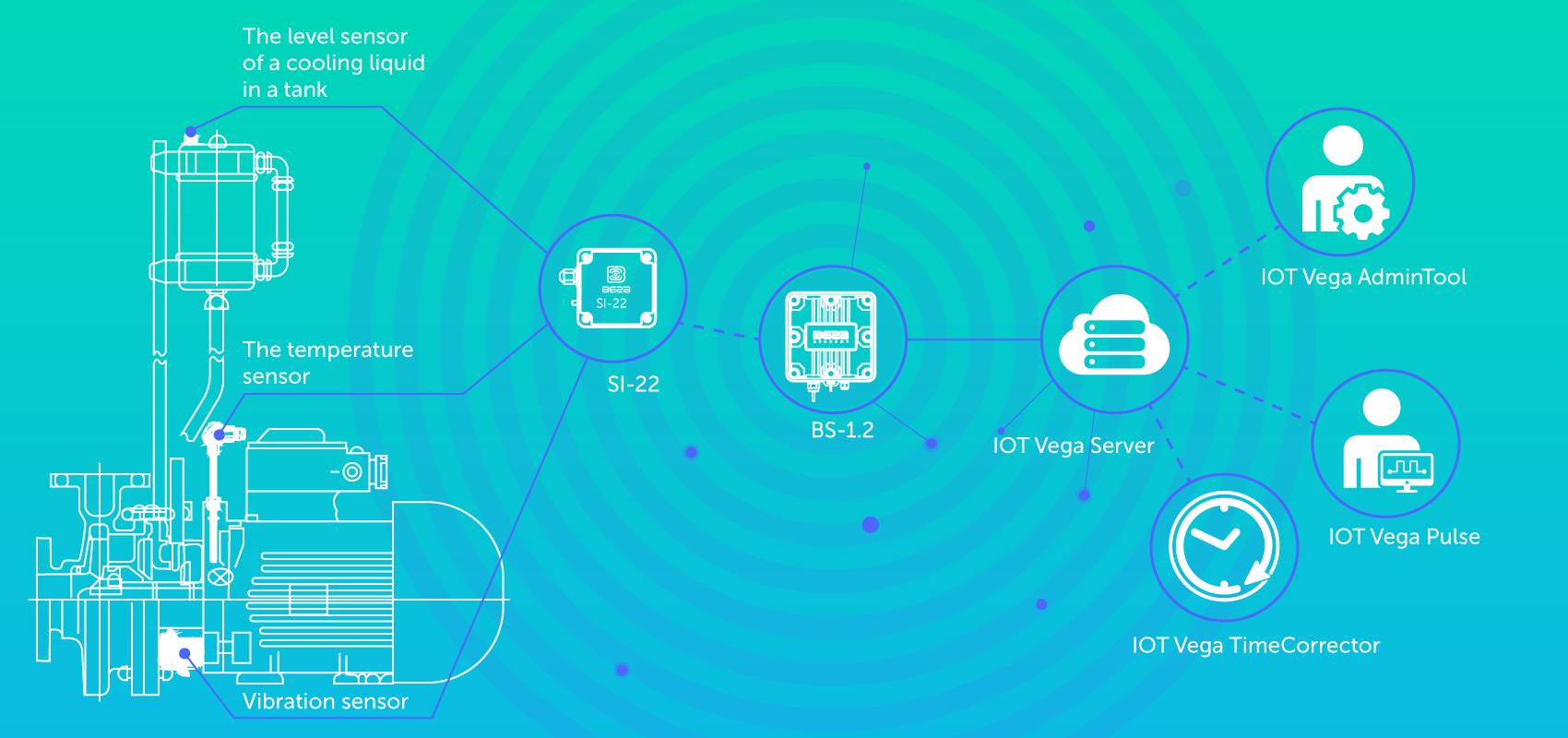

Telemetry of pumping equipment at the tank farm allows to get equipment operation status promptly and encrease work efficiency because of:

- decreasing downtime as a result of breakages;

- forecasting breakages and emergencies;

- planning timely repairs and service;

- staff reductions.

Result of IoT using is an increase of efficiency of processes monitoring and managing and in the end the profitability increasing.

Equipping the console pump with sensors allows you to receive real-time information about the following working parameters:

- pump's operation temperature;

- vibration;

- the presence of voltage in the mains;

- level of a cooling liquid;

- fluid leakages;

- impurities of dangerous gases in the air;

- repair needs.

The necessary sensors are installed on the pumping equipment, and then connected to the Vega SI-22 data collection device.

Full description of the solution and actual realization by our partners under the link.

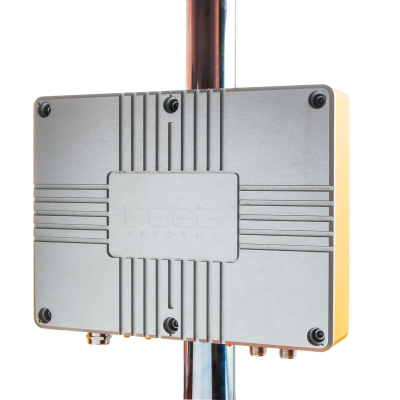

Vega BS-1

Vega BS-1 Vega BS-2

Vega BS-2 Vega BS-1.2

Vega BS-1.2 Vega BS-2.2

Vega BS-2.2 Vega BS-0.1

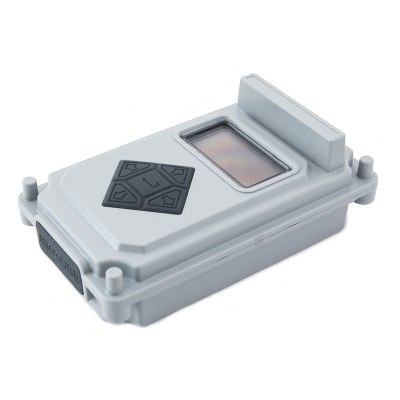

Vega BS-0.1 Vega BS-3

Vega BS-3 Antenna 868-01

Antenna 868-01 Antenna 868-01-A10

Antenna 868-01-A10 Vega SI-11

Vega SI-11 Vega SI-12

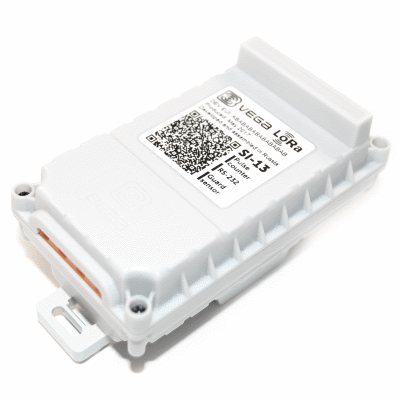

Vega SI-12 Vega SI-13-232

Vega SI-13-232 Vega SI-13-485

Vega SI-13-485 Vega SI-21

Vega SI-21 Vega SI-23-232

Vega SI-23-232 Vega SI-23-485

Vega SI-23-485 Vega SI-22

Vega SI-22 Vega NB-11

Vega NB-11 Vega NB-12

Vega NB-12 Vega NB-13

Vega NB-13 Vega NB-14

Vega NB-14 Vega NB-15

Vega NB-15 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE Vega TL-11

Vega TL-11 Vega M-BUS-1

Vega M-BUS-1 Vega M-BUS-2

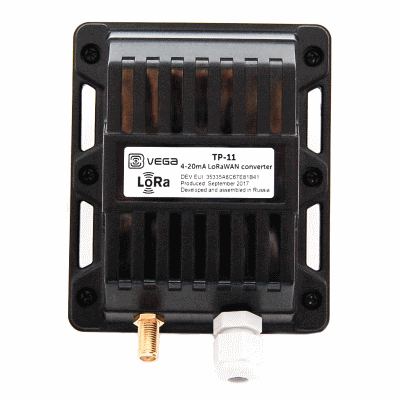

Vega M-BUS-2 Vega TP-11

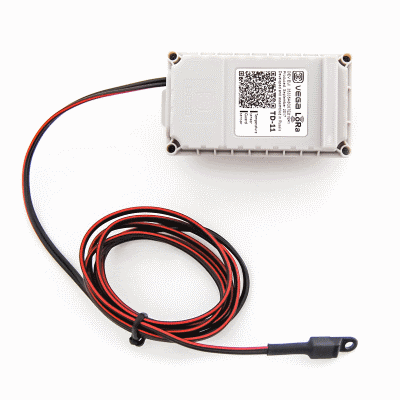

Vega TP-11 Vega TD-11

Vega TD-11 Vega GM-2

Vega GM-2 Vega SH-2

Vega SH-2 Vega LM-1

Vega LM-1 Vega LM-210

Vega LM-210 Betar-Vega SHVE/SGVE

Betar-Vega SHVE/SGVE CE2726A R01

CE2726A R01 CE2726A W03

CE2726A W03 CE2727A R02

CE2727A R02 CE2727A B04

CE2727A B04 Mercury 206

Mercury 206 Betar-Vega SGBM-1.6

Betar-Vega SGBM-1.6 Vega TS-11

Vega TS-11 Vega Smart-UM0101

Vega Smart-UM0101 Vega Smart-HS0101

Vega Smart-HS0101 Vega Smart-MC0101

Vega Smart-MC0101 Vega Smart-WB0101

Vega Smart-WB0101 Vega Smart Badge

Vega Smart Badge Vega TD-21

Vega TD-21 Vega Smart-AS0101

Vega Smart-AS0101 Vega Smart-MS0101

Vega Smart-MS0101 Vega Smart-SS0101

Vega Smart-SS0101 Vega DP-1

Vega DP-1 Vega USB-UART

Vega USB-UART Vega FSK Dongle

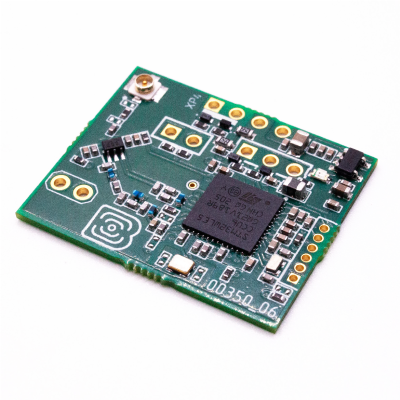

Vega FSK Dongle Vega RF32WL

Vega RF32WL Vega RM868-UFL

Vega RM868-UFL Vega RM868-CPA

Vega RM868-CPA VEKTOR-101

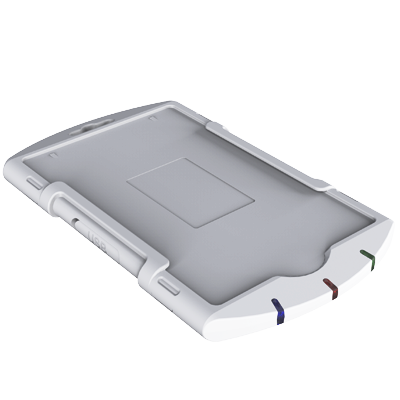

VEKTOR-101 Vega Smart Tab

Vega Smart Tab Vega BP 3.6V

Vega BP 3.6V Vega Smart Tab-S

Vega Smart Tab-S Vega BS-4

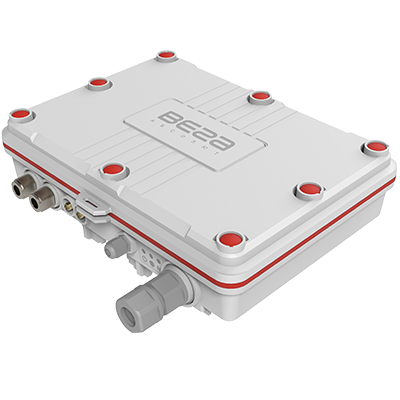

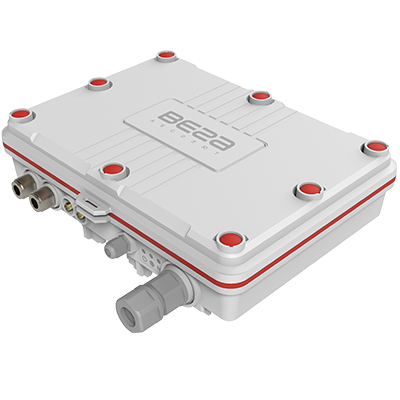

Vega BS-4 Vega BS-4 PRO

Vega BS-4 PRO